You lift your morning coffee mug only to find a spreading puddle beneath your Keurig—again. That frustrating ring of water on your counter isn’t just a cleanup headache; it’s a warning sign your machine is under hydraulic stress. When your Keurig leaks after brewing, it’s usually fighting pressure imbalances from blockages or failing seals, not random malfunctions. Left unchecked, this post-brew leakage can corrode internal components and create electrical hazards within weeks.

This guide cuts through the confusion with targeted fixes verified by Keurig’s engineering specs. You’ll discover exactly why water appears after brewing (hint: it’s rarely the K-Cup), how to diagnose leak patterns in 30 seconds, and which $0 household solutions stop 80% of leaks. Most importantly, you’ll learn the critical overfill mistake that spikes internal pressure to 4.5+ bar—shattering your machine’s 2.5-3.0 bar design limits.

Pinpoint Your Leak Source in Under 2 Minutes

Base Pooling: The Silent Pressure Killer

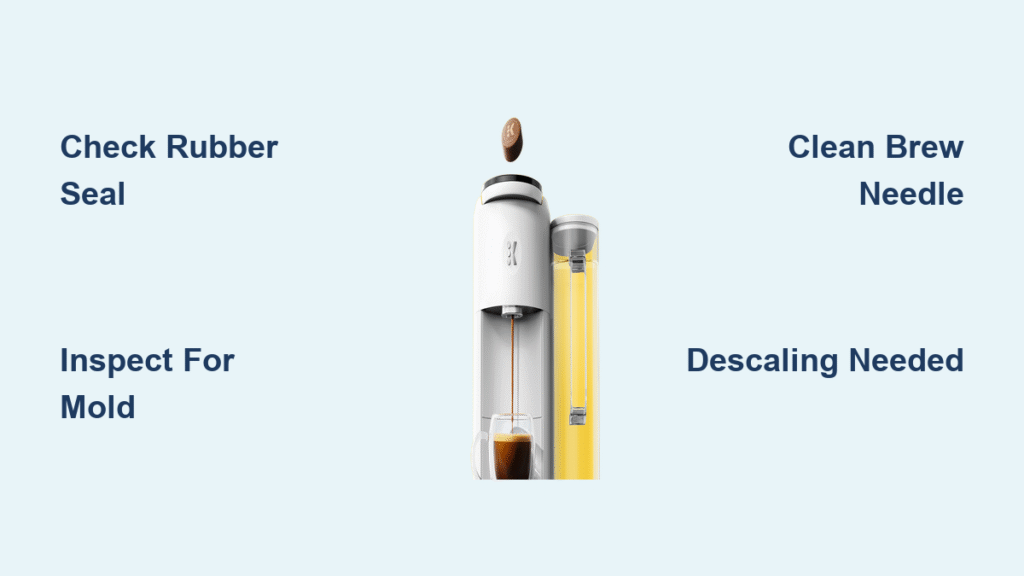

Water pooling under your Keurig after brewing almost always means internal pressure forced water past compromised seals. Don’t mistake this for normal condensation—true leaks leave distinct trails. Immediately check:

- Drip tray overflow: Remove the tray and inspect drainage holes. Coffee grounds clogging these ports cause water to back up into the machine base during brewing cycles. If residue coats the tray’s underside channels, mineral deposits are likely restricting flow.

- Tank seal failure: Run your finger along the machine’s rear base while brewing. Moisture here indicates the reservoir’s O-ring isn’t sealing properly, letting pressurized water escape during the critical depressurization phase after brewing.

- Internal hose cracks: Feel for dampness on the machine’s bottom panel during operation. Leaks here often start small but accelerate as thermal cycling (0.1-0.3mm clearance shifts) widens cracks.

Upper Assembly Drips: Misalignment or Gasket Failure

Water dripping around the reservoir or lid after brewing points to two specific issues:

- Reservoir gasket displacement: Remove the water tank and examine the rubber seal where it meets the machine base. If it’s flattened, torn, or riding unevenly in its groove, pressurized water escapes as the system depressurizes post-brew.

- Fill valve obstruction: Lift the reservoir and inspect the float mechanism inside the fill port. Mineral deposits here prevent the valve from closing fully, causing overflow that mimics leaks. A white, crusty ring confirms scaling.

Hidden Internal Leaks: The Emergency Zone

These require immediate action—moisture near electronics risks short circuits. If you notice:

- K-Cup holder moisture after brewing: Excessive dampness here means the exit needle isn’t clearing grounds, creating backpressure that forces water into unintended channels.

- Electrical compartment dampness: Any moisture near wiring or circuit boards demands unplugging the unit now. This indicates seal failure allowing water migration during depressurization.

Execute the 10-Minute Leak Fix Protocol

Clean Critical Components in Sequence

Skip this order and you’ll miss hidden blockages causing post-brew leaks.

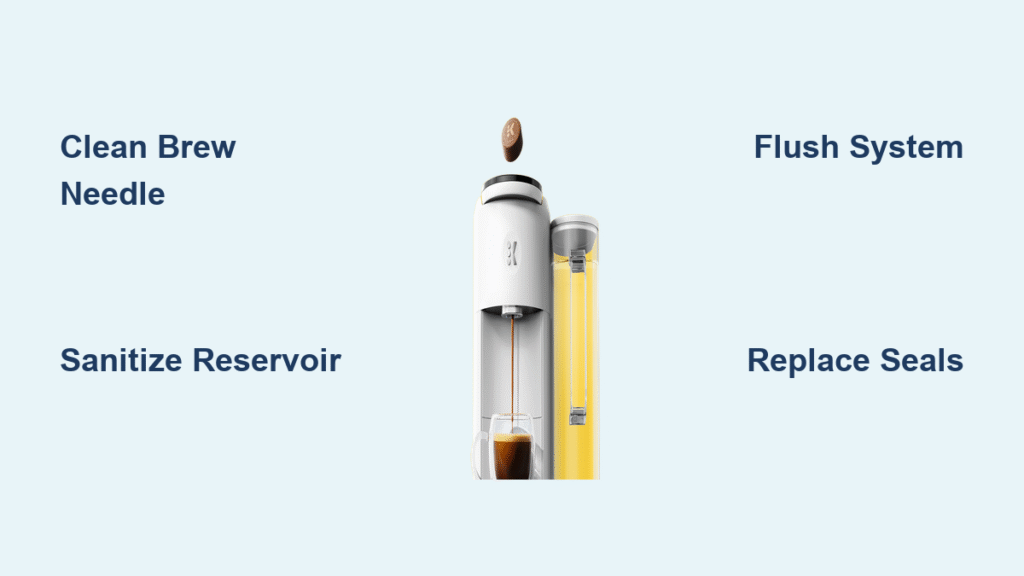

Reservoir Deep Clean

Empty the tank and focus on the base seal:

1. Wash the tank interior with warm soapy water, then rinse three times—soap residue attracts minerals.

2. Inspect the rubber gasket for tears or flattening. Gently reposition it into its groove if displaced.

3. Test the fill valve: Insert a toothpick into the port to ensure the float moves freely. Mineral buildup here causes 30% of “leaks” from overflow.

K-Cup Holder Needle Maintenance

This fixes 60% of post-brew leaks:

1. Remove the pod holder and turn it upside down.

2. Locate the lower exit needle (a metal tube protruding from the base).

3. Insert a straightened paperclip from the bottom up and wiggle gently—never force it. Grounds trapped here create backpressure that forces water out during depressurization.

4. Reinstall and run two water-only brews to verify smooth flow.

Drip Tray Unclogging

A blocked tray causes water to backflow into the machine:

– Disassemble all tray components and clear drainage holes with a toothpick.

– Wipe the counter area where the tray sits—residual moisture here worsens seal deterioration.

Descaling: The Pressure Reset

Mineral scaling restricts water flow, causing pressure to spike after brewing when the system depressurizes. Use this exact sequence:

- Mix equal parts white vinegar and water (never exceed the max fill line—overfilling creates 50% more pressure).

- Run 3-4 brew cycles without a K-Cup.

- Let the solution sit for 30 minutes to dissolve scale in critical pressure zones.

- Flush with 5-6 plain water cycles until vinegar smell vanishes.

Pro Tip: In hard water areas (>120 ppm), descale monthly. Filtered water reduces scaling by 60-85%, extending seal life 2-3x.

Fix Reservoir Seal Failures (The #1 Leak Cause)

O-Ring Realignment That Actually Works

Misaligned reservoir seals cause 70% of base pooling. Do this:

- Lift the tank straight up—no twisting—and inspect the O-ring. If it’s pinched or stretched, it won’t seal during depressurization.

- Clean the groove with a damp cloth, then roll the O-ring into place evenly using your thumb.

- Reinstall with firm downward pressure until you hear a distinct click. Test by gently wiggling the tank—it shouldn’t move.

When Replacement Is Non-Negotiable

Replace the O-ring or tank if you spot:

– Visible cracks: Hold the reservoir up to bright light and rotate slowly. Hairline fractures often appear near handle attachments.

– Permanent flattening: A compressed O-ring won’t regain its shape, failing to seal during post-brew pressure drops.

– Critical: Always apply food-grade silicone grease sparingly before installing new parts—dry seals tear instantly under pressure.

Prevent Leaks Before They Start

Daily Habits That Stop 90% of Leaks

- Never exceed the max fill line: Overfilling increases pressure to 4.5+ bar during depressurization, overwhelming seals. Fill to the line, not above it.

- Seat the tank firmly: Listen for the click—a loose tank allows water ejection during the critical 5-10 second depressurization phase after brewing.

- Wipe spills immediately: Coffee residue accelerates gasket deterioration by 40%.

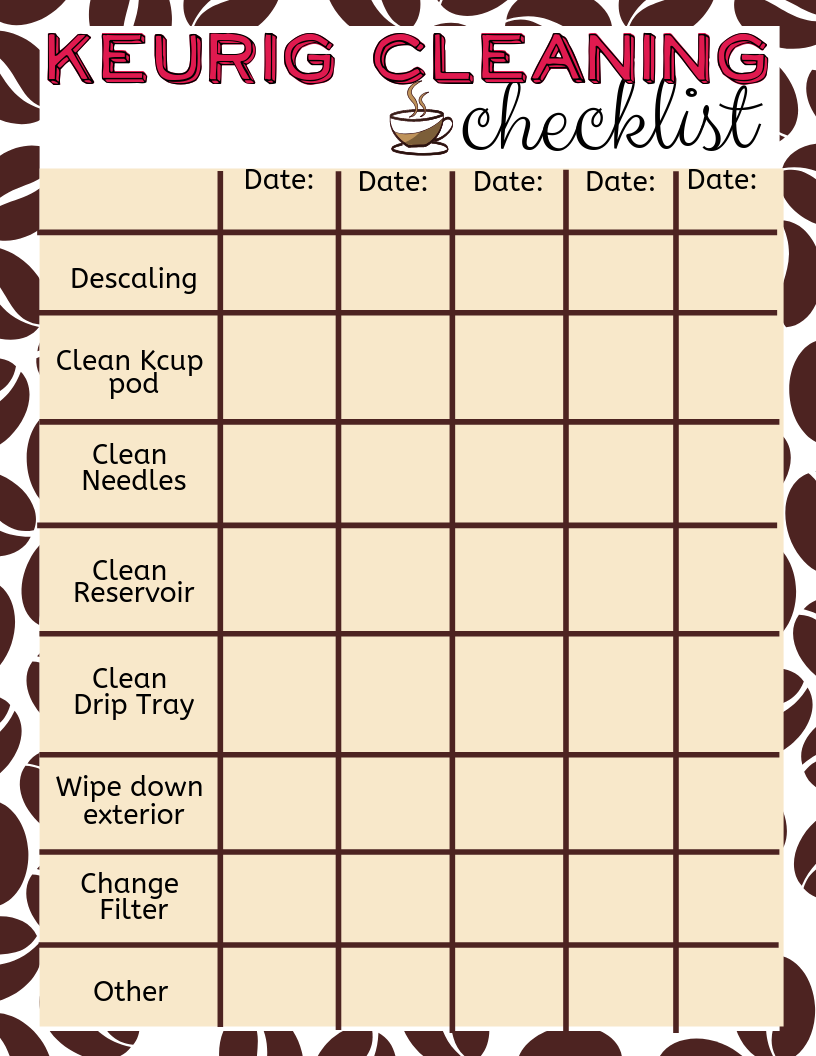

Monthly Maintenance That Pays Off

Spend 15 minutes monthly to avoid emergency repairs:

1. Descale using vinegar or Keurig-approved solution.

2. Clean both puncture needles with a paperclip.

3. Inspect all seals for early wear (look for whitening or stiffness).

4. Run a water-only brew to verify no leaks.

Usage Rules for Longevity

- Limit to 10 brews within 30 minutes—thermal stress from back-to-back cycles widens seal gaps.

- Wait 5 minutes between heavy usage sessions for components to cool and reseal.

- Store filtered water in the reservoir—mineral-free water prevents scaling that strains pressure systems.

Final Leak Repair Verification Checklist

Before declaring victory, complete these tests:

– [ ] Run 3 consecutive brews with regular K-Cups—no water should pool after brewing.

– [ ] Check the drip tray 10 minutes post-brew—only normal condensation (1-2 tsp) is acceptable.

– [ ] Confirm consistent volume—if coffee output drops more than 5%, residual blockages remain.

– [ ] Listen for gurgling—unusual sounds during depressurization indicate flow restrictions.

Success confirmation: After 24 hours of normal use with no new puddles, your Keurig leak repair is complete. Schedule monthly descaling reminders—this single habit prevents 80% of recurring leaks. Remember: that post-brew puddle isn’t random; it’s your machine screaming about pressure imbalances. Fix the root cause now, and reclaim your counter (and your sanity) for good.